--13668662966

Stirring tank is used for flotation reagent preparation, slurry storage and mixing of materials in other industries. Stirring tank is an indispensable equipment in the production process of single tank flotation machine. According to different uses, it can be divided into four kinds: slurry stirring tank, stirring storage tank, lifting stirring tank and reagent stirring tank.

Classification of agitating tanks

1. Slurry agitator

Slurry agitation tank is used for pulp agitation before single-tank flotation machine operation to suspend ore particles and fully contact and mix with reagents to create conditions for separation operation. It can also be used as pre-desilication tank, post-dissolution tank, desilication tank and seed separation tank in alumina production. It can also be used for similar operations in other industrial production.

2. Stirred tank

Stirring tank is used for pulp mixing and storage, not only for concentrators, but also for other industrial production departments. Large stirring tanks are also needed for pipeline transportation of black and non-ferrous metal concentrate slurry and coal slurry.

3. Lifting agitator

The lifting agitator has both agitating and lifting functions, and the lifting height can reach 1.2m. When the equipment configuration causes insufficient difference of pulp self-flow height, or when the difference is relatively small, it is not suitable for pumping, this kind of equipment can be selected.

4. Pharmaceutical Stirring Tank

Drug agitator is used for the preparation of various reagents in flotation plant. Because of the different properties of reagents, the material and structure of agitator tank of single cell flotation machine are also different.

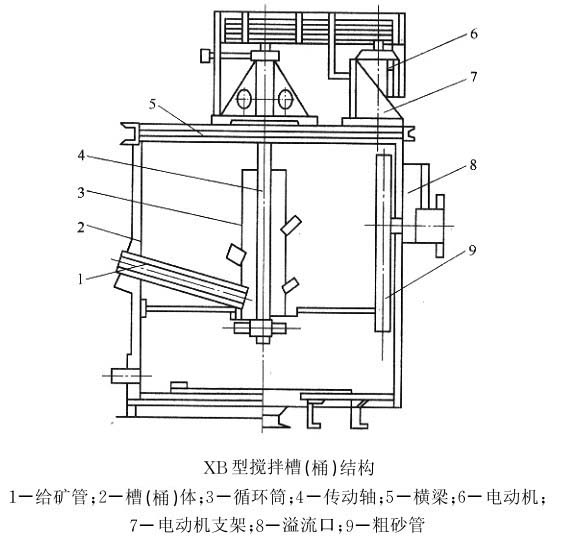

At present, there are no finalized series products in the special acid-and alkali-resistant pharmaceutical stirring tank. Pulp mixing tank is the most widely used one. According to the different properties of the stirred material and the required suspension degree, there are slight differences in its structure. For example, the lowest and medium suspension stirring generally adopts single impeller without circulating cylinder structure, and the impeller speed is lower; the highest suspension stirring needs to adopt circulating cylinder structure or multi-impeller structure, and the impeller speed is higher; the structural characteristics of high concentration stirring tank is impeller. Both the diameter and the diameter of the circulating cylinder should be increased.