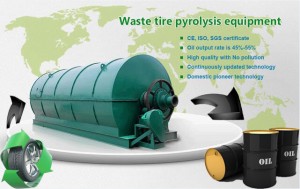

Waste rubber pyrolysis oil equipment

A.waste rubber pyrolysis oil equipment process

Waste rubber pyrolysis oil equipment is waste tires, waste rubber and other impurities into the reactor, the high temperature heating waste tires and plastic catalytic cracking heating, slipping out of oil vapor, oil and light through the light and heavy components separation device, light components Into the condenser, while uninterrupted discharge automatically slag, liquefaction part of the condensation of tire oil, non liquefaction part of the gas purification system through the input heating system combustion.

B.The characteristics of waste rubber pyrolysis oil equipment:

1.Safety

Provide negative pressure device, low pressure, more secure.

2. Environmental protection

Waste gas waste treatment, science and environmental protection will not produce any environmental pollution.

(1) Exhaust gas mainly refers to non-condensable gas, but combustible gas is mainly used for re-combustion of the reactor.

(2) The waste liquid is mainly discharged through the oil-water separator to the waste water sedimentation tank, after a period of precipitation treatment, recycling again.

(3) Slag mainly through the side of the reactor slagging, discharged from the reactor.

C. waste rubber pyrolysis oil equipment Product use:

Fuel oil application

Fuel oil: mainly used in steel mills, boiler heating, heavy oil generators, cement plants

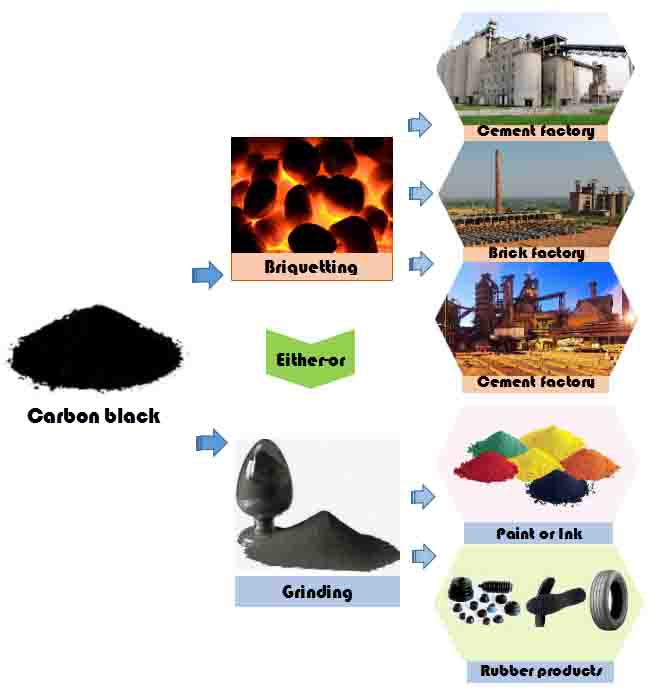

Carbon black application

Carbon black application

2. Carbon black: can be used for pressure ball burning, can also be used for refined toner. Refined toner can be used for new tires, rubber soles and pigments.

3. Steel wire: you can scrap recycling, can also be re-cast into other steel products.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection