Waste tire pyrolysis equipment

According to statistics, in 2013, the amount of waste tires produced in China was 10.18 million tons, and it is estimated that more than 20 million tons will be exceeded in 2020. Where is the growing number of used tires? In response to this social problem, DoingGroup used chemical cracking reactions, R & D out of waste tire cracking equipment. Our waste tire pyrolysis equipment, by more and more people's attention, every day from around the world to visit our factory visit our equipment, our equipment is so popular, is Because of its following advantages:

1. Reactor is produced according to the pressure vessel production standards, the use of 16mm thick boiler steel pipe and arc pressure head, can withstand high temperature and pressure.

2. High standard three-step welding process, not easy to rupture, long service life.

3. Pinion rotation device, small power, no direct contact with the reactor, heat transfer less easily deformed.

4. Three-stage cooling system with tube condenser, is the most commonly used in the oil industry, the best performance of the condenser. Make sure the fuel vapor is fully cooled and produces high volumes of oil.

5. Safety devices have oil-water separator, water seal, vacuum device. To ensure safe and stable operation of equipment.

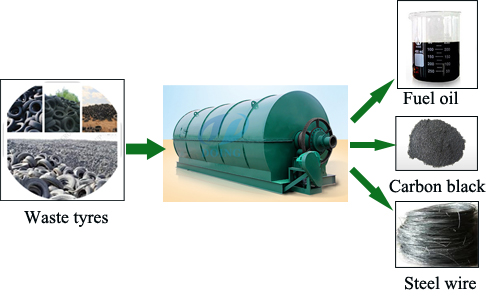

Waste tire pyrolysis equipment working process:

1, First of all, the waste tires from the feed door into the host reactor, close the feed door, sealed. Heat the main furnace with fuel coal or wood in the heating chamber.

2, When the temperature reaches 220 ℃, oil and gas precipitation, into the buffer chamber, residual oil (containing some slag) sink to the residue tank.

3,Light oil automatically enters the cooling system, condensed into oil.

4 Non-condensable gas, it will return to the reactor, as the heating reactor fuel.

After the above process, you can get fuel, carbon black, steel wire, combustible gas, which cracked the material from the waste tire pyrolysis equipment has a wide range of uses:

Fuel oil application

Fuel oil can be used in steel mills, boiler heating, heavy oil power plants and cement plants to produce refined diesel for further processing and diesel generators, light fuels, heavy machinery.

Carbon black application

2. Carbon black can be used for pressure ball burning, refined toner. Can be used for new tires, rubber soles, pigments made of refined toner.

3. Steel wire is mainly used for scrap recycling, and re-cast into other steel.

4. Combustible gas is mainly used for circulating heating reactor.

Outstanding highlights of our waste tire pyrolysis equipment is energy saving, low investment and high yield. Market prospects will be more and more broad, any machine problems, please contact us !!!

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection