86-0535-2422021

Product Description

This is a unique product in the automatic concrete mixer market. The fifth generation self-feeding mixer upgrades the bucket down function to truly realize the multi-purpose loading function of the machine. At the same time, the brake caliper increases the braking performance and matches the high-pressure car wash. The equipment is kept clean, and the water tank is increased to increase the output... So far, the fifth-generation product truly realizes the multi-purpose function of the loading function, the stirring function, the transportation function, and the car washing.They provide excellent maneuverability (rotatable cab operating table and drum rotation system) , flexibility and autonomy. Equipped with an innovative computerized production system capable of producing high quality concrete.

rotatable cab in front and rear, the moving arm and the drum can both be horizontally rotated by -90°~+90°and bucket down function. The consistency, repeatability and quality of the concrete batch are the 4 major advantages we can guarantee. This is the unique feature of our product.

The extremely compact, flexible and reasonably priced vehicle can unload 1.5m³ of concrete at one time. It can work continuously for 24 hours a day with no stop, and the daily output (8 hours) is 84 m³.

No need mixer, concrete carrier and loader,save 100 degrees power and save at least 3 labours per day!

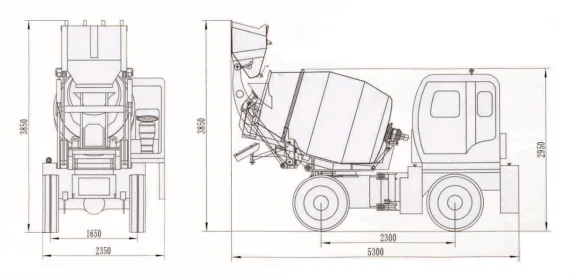

Specifications for HB2500 Self Loading Concrete Mixer | |||

Overall size(mm) | 5300*2350*2950 | ||

Wheelbase(mm) | 2300 | ||

Weight(kg) | 7500 | ||

Engine | YuChai 4102 Supercharged | ||

Power(kw) | 78(105Hp) | ||

Gearbox | 280 separated | ||

Drive axle | 2.0T Wheel axle reduction bridge | ||

Tire | 16/70-R22.5 | ||

Bucket capacity(m³) | 0.5 | ||

Drum capacity(m³) | >=1.8 | ||

mixing capacity | >=1.5 | ||

Reduction ratio | 1:24 | ||

Rotating speed(laps/minute) | >=15 | ||

reducer | Chinese brand | ||

Drum slewing angle | ±90 ° | ||

Tanks capacity | Water:1200L Diesel:110L Hydraulic:150L | ||

Gradeabiliy | 30 ° | ||

Loading qty | 2 units /40 HC | ||

Productivity | 10-12 m³/h | ||

Quality guarantee period | 6 months | ||

Production Process

1. Reduce the cost of consumption

No need to use a mixer, save 100 degrees every day, no concrete carrier, no loader loading, and save at least 3 workers per day!

2. One-piece feeding, convenient transportation and efficient production

The upgraded bucket down function, the fifth generation of products truly achieve the loading function, mixing function, transportation function, washing and other multi-purpose functions. Excellent handling, flexibility and autonomy.

3. Two-way driving

The cab operator station can be rotated to perform two-way driving in front and rear. No need to turn the head, and the work process is convenient and efficient.

4. Roller rotation system

The boom and the drum 2 can be rotated horizontally 90° at the same time, a total of 180°, flexible feeding and unloading.

5. Unloading is efficient

Tiltable unloading function for more complete discharge and faster speed

6. High-end configuration, superior performance and simple operation

Vacuum high pressure tire with five layers of steel wire

Upgraded bucket down function

Brake tongs increase brake performance

The material of the drum is manganese plate, which is more wear-resistant.

Up and down hinged beaded bearings are more durable, 15 times more than traditional craftsmanship

The touch screen is quantitatively added with water to make the mixing more uniform and more in line with the standard.

Camera to increase the line of sight and eliminate blind spots in the cab

High performance electronic fan radiator

Self-contained water pump, easy to add water

Self-contained car wash gun, easy to wash car

Comes with a fan, optional air conditioning, refreshing and not stuffy during the whole work process

7. Factory direct sales

No middlemen make a difference