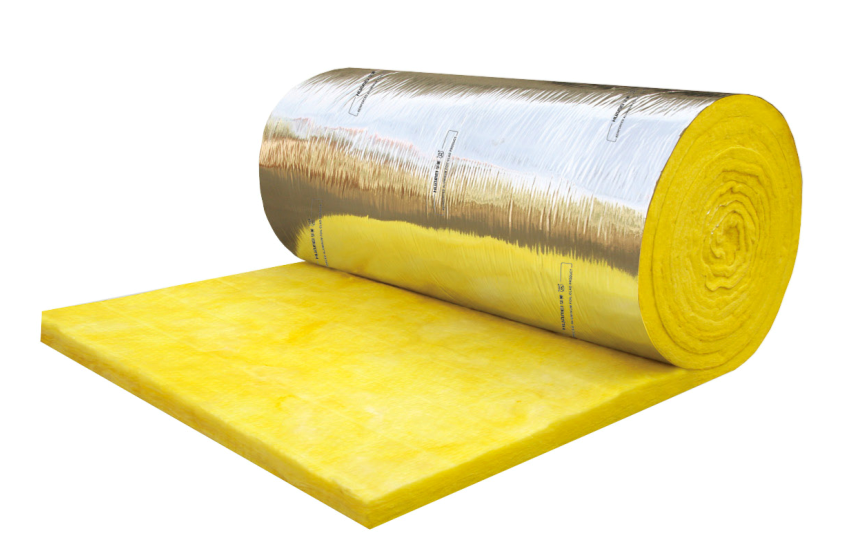

Glass wool blanket introduce

Glass wool production lines employing latest-generation technology to manufacture boards, slice, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, centrifuged to fiber, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

Glass wool is mainly with four kinds of colors, which are yellow, white, pink and black, as well as four different facing which are FSK, Kraft, white cover, and BGT.

Distinctive Advantages Glass Wool Insulation Blanket:

Excellent thermal, acoustical properties.

Light weight and easy to fabricate on job site.

Non-combustible and fire-retardant.

Very economical.

Durable, life-time and termite proof.

Applications of Glass Wool Insulation Blanket:

Glass Wool Insulation is light and easy to install at office building, modern entertainment centre, roof, HVAC system and also other residential, industrial buildings such as:

Walling and partitioning; Faced and external walls; Suspended ceiling; Steel structures; Prefabricated houses; HVAC Duct works.

Glass wool Parameters:

| Item | Unit | Index | Standard |

| Density | kg/m3 | 7-50 | GB/T 5480.3-1985 |

| Average fiber dia | μm | 5.5 | GB/T 5480.4-1985 |

| Water content | % | ≤1 | GB/T 3007-1982 |

| Grade of combustibility | Non-combustible Grade A | GB 8624-1997 | |

| Reshrinking temp | °C | ≤480 | GB/T 11835-1998 |

| Thermal conductibility | w/m.k | 0.034-0.06 | GB/T 10294-1988 |

| Hydrophobicity | % | ≥98 | GB/T 10299-1988 |

| Moisture rate | % | ≤5 | GB/T 16401-1986 |

| Sound absorption coefficient | 1.03 product reverberation method 24kg/m32000HZ |

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection