Basic Info

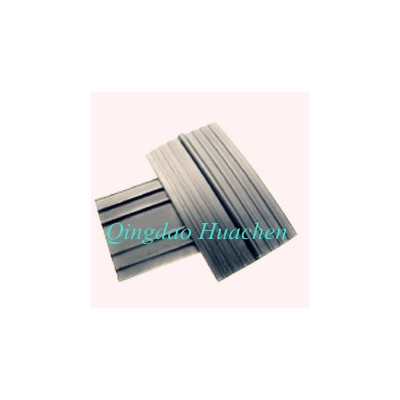

Material: EPDM

Usage: Industrial

Color: Black

Product Description

1. Product Performance and Characteristic

The product is use of the high elasticity and compression deformation of rubber. It can produce elastic deformation in all kinds of load, and can fastening the seal. It playing an effectively role of prevent the construction component of water leakage, seepage, and shock absorption. So as to ensure that the service life of the engineering construction.

2. Product Usage

A. Mainly used for infrastructure projects, underground facilities, tunnels, water conservancy, metro project.

B. For the gate, dam construction, engineering, underground structures with adjustable concrete pouring.

In the process of water stops in positioning and concrete pouring, we should pay attention to positioning method and poured pressure, in order to avoid water stops punctured and the influence of water stops effect.

| Items | index | |||||

| B | S | J | ||||

| 1. Hardness ( Shore A ) | 60±5 | 60±5 | 60±5 | |||

| 2.Tensile strength ,MPa ≥ | 15 | 12 | 10 | |||

| 3.Elongation at break , % ≥ | 380 | 380 | 300 | |||

| 4.Compression set % | 70ºC×24h,% ≤ | 35 | 35 | 35 | ||

| 23ºC×168h,% ≤ | 20 | 20 | 20 | |||

| 5.Tear strength,KN/m ≥ | 30 | 25 | 25 | |||

| 6.Brittleness temperature,°C ≤ | -45 | -40 | -40 | |||

| 7.Air aging | 70ºC×168h | Hardness ( Shore A ) ≤ | 8 | 8 | -- | |

| Tensile strength,MPa ≥ | 12 | 10 | ||||

| Elongation at break , % ≥ | 300 | 300 | ||||

| 100ºC×168h | Hardness ( Shore A ) ≤ | -- | -- | 8 | ||

| Tensile strength, MPa ≥ | 9 | |||||

| Elongation at break , % ≥ | 250 | |||||

| 8. Resistance ozone ageing 50pphm: 20%, 48h | 2grade | 2 grade | 0 grade | |||

| 9. Adhesion of rubber to metal | With contact section in elastomer | |||||

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection