Power:

Power:

Rongtai provides a stable and efficient induction power supply system for the market, which can provide the best power supply selection according to different applications.

● The latest generation of digital computing technology, microcontroller program control

●Low start frequency, ultra low power oven

●The rectification is full, the power factor is high, and the high harmonics are small.

● Equipment power utilization is close to 100%

●The liquid metal production capacity is higher, and there is no need to increase the power demand.

● Efficiently match production to different metal liquid demand levels

● Fiber transmission trigger signal, electronic control adopts digital mode

●Competitive power consumption indicators

●Electrical safety design standards in line with international and domestic standards

● More sophisticated and intelligent protection

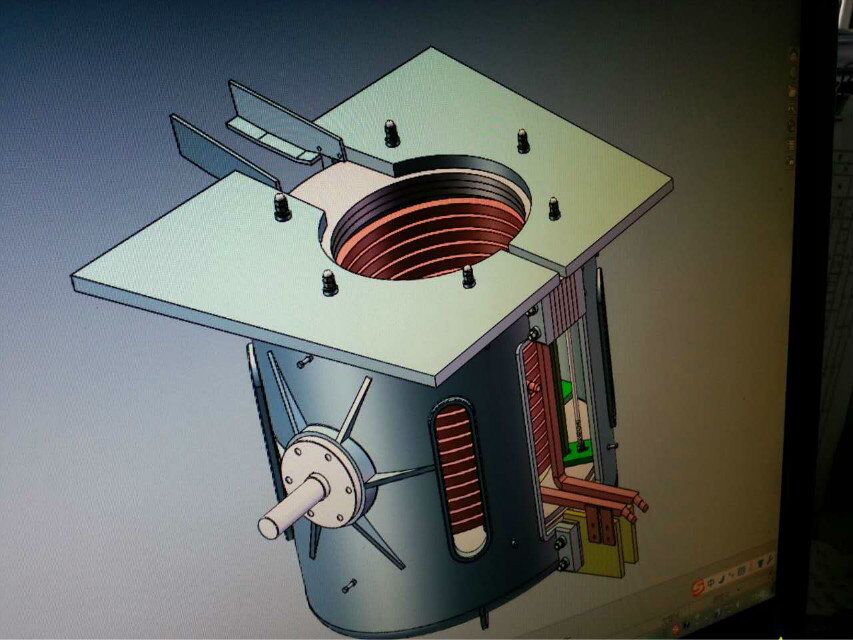

Furnace body:

Furnace body:

● Low installation cost: This electric stove is ideal for height restrictions due to headroom. And because the pits that need to be excavated are shallow, this also reduces installation costs.

● Low cost of scrap: Compared to a standard size melting furnace of the same metal liquid capacity, this electric furnace has a larger opening diameter of 20-30%, so the foundry can use a larger volume (and usually lower price). . For foundries with large return stock and long risers, which are particularly common in ductile iron workshops, this large furnace can reduce cutting labor and associated waste disposal costs.

● Slag removal is more convenient: the large furnace mouth is also beneficial to remove all kinds of slag accumulated on the furnace wall. This function is especially important when the non-ferrous metal melts and the staff of the melt-operated platform must extend the refractory slag equipment into the bottom of the furnace.

● There are many expansion functions: the slag discharge device, the lining launching system and the pit protection device can be installed to improve the convenience and safety of the smelting operation; various smoke collectors and hoods can be installed to achieve the MACT standard, etc. The most stringent air pollution requirements.

●Casting automation: Weighing frame can be weighed in real time to weigh the weight of molten iron, and transfer various production data to the factory production process execution system (MES) for intelligent factory management.

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection