Product Description

Waste rubber pyrolysis plant

Nowadays ,waste rubber pollution is becoming more and more serious damage to our environment. In order to achieve the recycling of waste rubber, DoingGroup has developed a waste rubber pyrolysis plant, but also can be used for waste plastics, waste tires and other waste reprocessing.

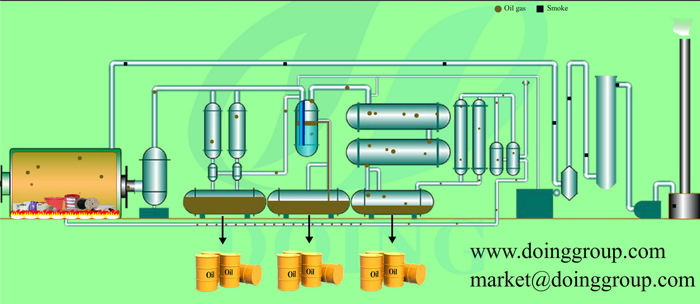

Waste rubber pyrolysis plant working process

Waste rubber pyrolysis plant working process

The following is a brief description of the process of rubber pyrolysis plant:

1. Use mechanical waste tires into the reactor, closing the entrance to prevent gas from flowing out.

2. Carbon, wood or fuel heating reactor, the reactor generally reach 200-300 degrees is the beginning of the cracking reaction, when the waste tires vaporized into oil vapor.

3. Oil and gas into the condensing system, liquefied into oil, was collected to the tank device. Our system has a negative pressure device, he can greatly improve the production of pyrolysis oil.

4. The liquefied petroleum gas that can not be liquefied under normal pressure will be returned to the reactor as fuel for combustion, which not only saves energy in environmental protection.

5. After completing the oil production, the reactor will be cooled. When the temperature drops to 40 degrees, the carbon black and wire will be removed automatically or manually.

Advantage of rubber pyrolysis plant

This waste rubber pyrolysis plant proved to be successful due to some advantages of it:

1. Reactor is made according to the standard of pressure production, using 16mm thick boiler special steel and arc compression head, can withstand high pressure and high temperature.

2. High-standard 3-step welding process, not easy to crack, long service life.

3. Pinion rotation device, power is small, not directly contact the reactor, less heat transfer, not easy to deformation.

4. The three-stage cooling system uses tube condensation, also known as a heat exchanger, and is currently the most commonly used and best performing condenser in the oil industry. Can ensure that the cracked oil and gas fully cooled, high oil yield.

5. Safety device oil-water separator, water seal, vacuum device, to ensure safe and efficient operation of equipment.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com