Baling machine

Product introduction:

A baler is a machine used to bale grass. Has the following

characteristics:

1.A wide range of applications, can be used for straw, wheat straw, cotton stalks, corn stalks, canola poles, peanut vines. Straws and pastures such as bean poles are picked up and bundled;

2. The supporting functions are many, you can directly pick up the bales, you can also pick and bundle after cutting, you can also crush and then bundle;

3. The work efficiency is high, and you can pick up 120-200 mu of bales every day, and the output is 20~50 tons.

Product Categories:

This product is divided into hydraulic baler and tractor towed baler. From the original point of view, it is divided into corn straw baler, wheat straw baler, straw baler and so on.

product features:

1. Compared with the historical use of the hydraulic baler, the mechanism is simple, the performance is reliable, easy to operate, maintain, and has good usability and low maintenance cost. The annual use cost can be saved by more than 200,000 yuan.

2. There are no hydraulic drills, hydraulic valves, accumulators and other components necessary for the hydraulic baler. There is no lifting and lowering device for the stable change of the hydraulic system. The energy-saving effect is obvious. Compared with most balers in history, the energy consumption is 5KW per hour compared with similar products, and the annual electricity cost can be saved by more than 40,000 yuan.

3, and there is no hydraulic oil running, leakage, leakage phenomenon, is conducive to environmental protection.

4, easy to install, just do a roller, you can use it immediately, no need to debug. Vertical waist, waist buckle on top, steel bundle on top, steel bundle on the roller table, steel bundle does not scrape the side of the roller groove when moving on the roller table.

5, the operation is simple, to achieve remote operation, no need to increase labor, can be synchronized in the control room, no training [3].

6, low power, pure machinery, no pollution, in line with environmental and low-carbon national industrial policies.

Control maintenance:

1. according to the choice of two types of pick-up width, to adapt to different picking width operations, the strength is super strong.

2. The compression mechanism assembly is located on the upper part of the pickup mechanism assembly, and the same pick-up range, the device width is smaller, and it is more convenient for small field operations. The overall layout is more reasonable.

3. Technical features: The four-wheel tractor is being used for traction, and the operation is stable, which is convenient for matching and promotion.

4. The power input is equipped with a safety clutch. The main drive shaft, compression device and rope-binding device are equipped with safety bolts. When the system load is too large, the bolts are automatically cut, the power transmission of the tractor is cut off, and the protection system is not damaged.

5, using the German imported Rassdive knotter, can adapt to different biological materials baling operations, firm and reliable, and can adjust the length of different bales, efficient and flexible.

6, automatic picking up straw, weeds, automatic separation of mud sand, automatic feeding, automatic compression, automatic rope, automatic out of the package, the entire process of automatic operation, easy to operate, high efficiency. The profiler wheel is mounted on both sides of the pick-up, so that the picker can maintain proper distance from the ground and good profiling performance. The upper end of each of the racks of the picker is slightly up-tilted, which is convenient for the grass to pick up and clean, and the hard objects such as stones can automatically avoid.

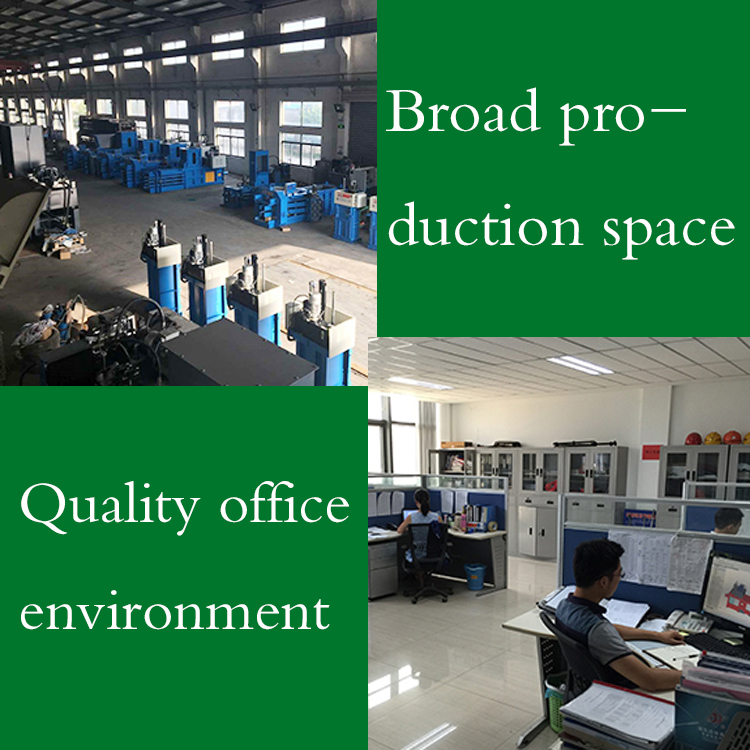

Company Information:

Our company was founded in 2008. It is located in Jinan.It is a collection of agricultural machinery. R & D, production, sales as one of the technology-oriented enterprises, the main products are green storage balers, straw silage balers, straw balers, corn balers, round balers and other livestock farming machinery, pastoral management machinery . The company has 3 senior technical staff, 5 middle management personnel and 56 workshop employees. In 2015, the company started to build a complete set of equipment for animal husbandry and forage storage--automatic silage round bale coating unit, which has been well received by users, and realizes automatic flow operation of straw crushing, bundling and coating. Its automation level has reached international advanced level. Level, lead the new development of forage silage industry and promote the comprehensive utilization of straw, realize the convenience of forage harvesting, storage and transportation, and make a major contribution to the recycling of straw.

Packaging And Shipping:

Our certificate:

After our efforts, our company got the qualification certificate and company honor certificate in 2016.

FAQ:

Our Services:

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection