Description

Carbon Block Cartridge Filters are made of activated carbon block which is manufactured by strictly extruded controlled engineering processes,

advanced techniques and FDA approved material of the high quality activated carbon guarantee excellent durability, minimal pressure loss and high flow rate. Carbon block cartridges are highly effective in removing odour, bad taste, chlorine spores and microorganisms in water. Carbon block cartridge filters provide economic solution for a wide range of residential, commercial and industrial water filtration processing.

Feature

1. Multiple sizes of carbon filters are available for custom

2. High chlorine taste & odor and bad taste & odor reduction

3. Efficient filter material, economic prices with extended service life

4. Extensive chemical compatible ability, so wide range in application

5. Enhanced dirt holding capacity, low pressure drop and high flow rate

6. FDA approved material good absorbency and no carbon fines release

Application

1. Chemicals

2. Electronics

3. PCB industry

4. Drinking Water

5. Plating Processes

6. Food & Beverages

7. Pre RO/DI Filtration

8. Waste Water Treatment

Specification

| Filter Media | Coal, Coconut Shell Activated Carbon |

| Length | 5", 9.75", 9.8", 10", 20", 30", 40" (According to customers requirements) |

| Inside Diameter | 28mm, 30mm (Special ID can be customized) |

| Outside Diameter | 2.5"(63mm), 2.55"(65mm) Special OD is accepted |

| Filtration Rating | 5μm, 10μm |

| End Cap | Polypropylene |

| Inner/Outer Wrap | Polypropylene Non-woven fabric |

| Gasket/O-ring | Silicone, Buna-N, EPDM |

| Netting | Polyethylene |

Performance

Operation Data for Carbon Block Cartridge Filters

| Maximum Operating Temperature | 80℃(176℉) |

| Max. Differential Pressure | 7.0 bar at 25℃ (100 psi at 77℉) |

| Max.Operation Pressure | 17 bar |

| Recommended Change Out Differential Pressure | 2.1 bar (31 psi) |

| Max. Flow Rate | 5 L/min ( water, △P=0.15kgf/c㎡, 10" Carbon Block Cartridge) |

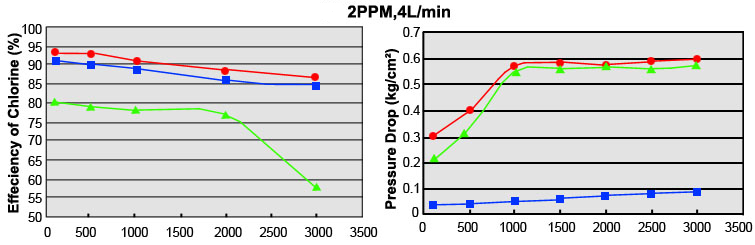

Efficiency & Flow Rate 10" CTO Carbon Block Cartridge Filters

Removability to Multifarious Impurities

| Remaining chloride | Chemical oxygen demand | Total iron | Oxide | Mercury | As | Cyanide | Phenol | Sixivalency |

| 93.83% | 43.21% | 91.88% | 67.32% | 79.43% | 38.51% | 99.98% | 78.85% | 8.77% |

Average Adsorption to Poison Substance for 10" Carbon Block Cartridge Filters

| Benzne | Toluene | Methanol | Ethoxy | Chloroform | Acetone | Styrene | Hyaarogen sulphide | N-butyl sulfhydrate |

| 68g | 81g | 69g | 91g | 120g | 72g | 60g | 125g | 171g |

Technical Index of Activated Carbon

| Ratio for surface area | 800 - 1000 m²/g |

| Adsorption for iodine | 900-1000 mg/g |

| Adsorption for Benzene | 20-25% |

| Adsorption for carbon tetrachloride | 50-60% |

| Adsorption for Methylene Bule | 13-16ml/g |

| Ash content | ≤3.5 |

Tech Support

| Construction of Carbon Block Cartridge Filters | ||

| ● Outer layer is polypropylene non-woven fabric to filter the impurities & sludge ● Inner layer has high quality PP non-woven fabric to block carbon powder drop of ● Carbon block cartridges can be made of coal & coconut shell accodring to requirement ● The length size of OD and ID can be manufactured according to customer's requirement ● End cap is made of FDA approved polypropylene material, it is reliably sealing & durable ● A variety of filtration rating to ensure high filtration efficiency of remove residual chlorine ● O-ring can be made of Silicone, Buna-N, EPDM, high temperature resistant & good sealing | |

Oder Information

| CTO | Filter Material | Length | ID | OD | Micron Rating | Gasket/O-ring |

CTO Series Extruded Carbon Block Cartridge Filters | A = Coal | 5 = 5" | C = 28mm | M = 2.5"(63mm) | 5 = 5μm | S = Silicone |

| 9.75 = 9.75" | ||||||

| 9.8 = 9.8" | ||||||

| 10 = 10" | E = EPDM | |||||

| B = Coconut Shell | 20 = 20" | D = 30mm | F = 2.55"(65mm) | 10 = 10μm | ||

| 30 = 30" | U = Buna | |||||

| 40 = 40" |

For Example:

CTO-B-10-C-M-5-S

CTO Series Extruded Carbon Block Cartridge Filters - Coconut Shell - 10" - 28mm - 63mm - 10μm - Silicone

Special CTO Series Extruded Carbon Block Cartridge Filters can be customized, such as special ID, OD, length and end caps etc.

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection