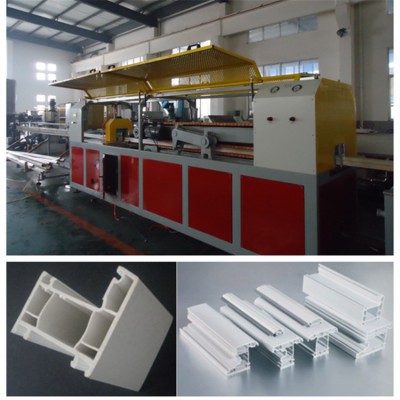

PVC window and door profile extrusion production machine

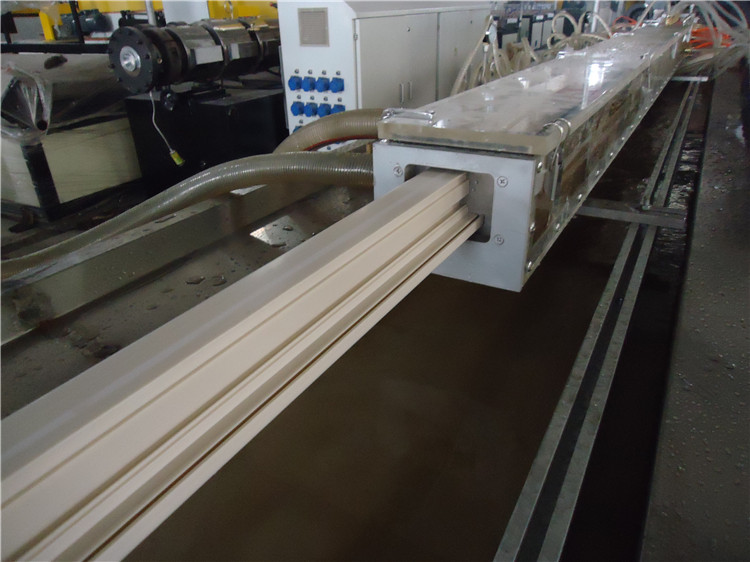

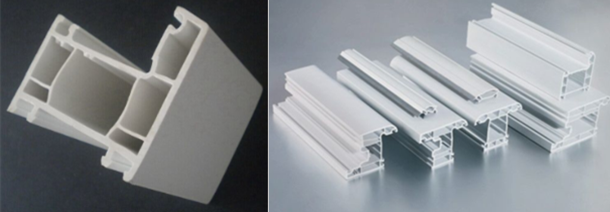

1. The production line uses conical twin screw extruder. It can produce PVC door and window profile, aluminium -plasitc composite profile and cross section cable, pipes, etc

2. It's optimized designed introducing new technology. the line has features: stable plasticization, high output, low sheering force, long line service and other advantages. after simple changing of the screw, barrel and moulds, it can also produce foam profiles.

parameters of the PVC window and door profile extrusion production machine:

| model | YF108 | YF180 | YF240 | YF300 | YF400 | YF500 | YF600 |

| max width | 108MM | 180MM | 240MM | 300MM | 400MM | 500MM | 600MM |

| extruder | SJZ51/105 | SJZ51/105 | SJZ65/132 | SJZ65/132 | SJZ80/156 | SJZ80/156 | SJZ80/156 |

| main power | 18.5KW | 22KW | 37KW | 37KW | 55KW | 55KW | 75KW |

| capacity | 100KGH | 100-150KGH | 150-200KGH | 150-200KGH | 250-300KGH | 250-300KGH | 300-350KGH |

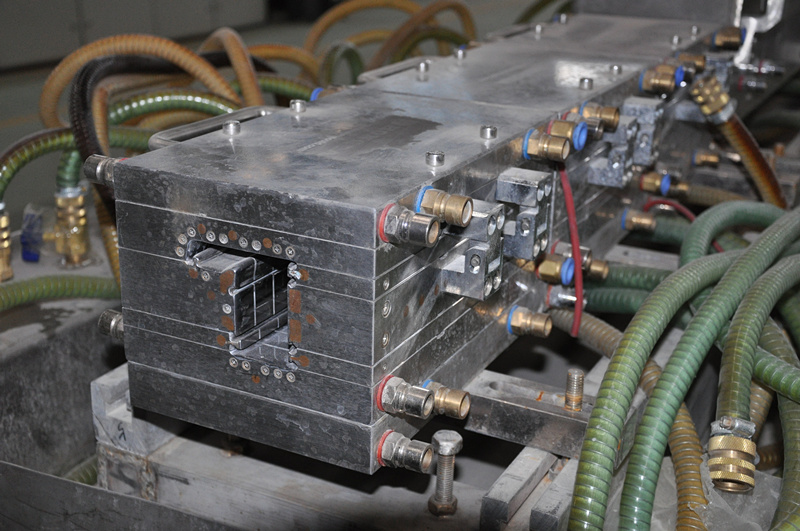

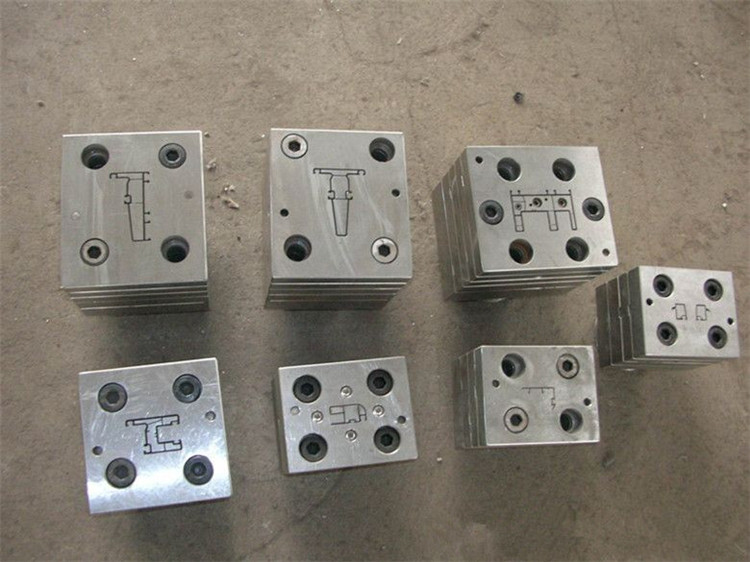

photos of PVC window and door profile extrusion production machine

Our factory information and photos:

Jiangsu xinrong science and technology development co.,ltd.

founded in 1996, 22 years manufacturing experience.

with more than 20 machine patents

more than 50000 square meters factory

passed ISO9001,2000 certificate; CE certificate, TUV certificate.

export over 65 countries

100% raw material from ISO certified factory

machine warranty 18 months

provide factory design and turn-key solutions

50 senior engineers are at your servince in anytime.

We take part in Chinaplas exhibition every year and also overseas exhibition

Outside view photo of our factory:

our engineer photos

our certification:

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection