silicon carbide sisic heat exchanger with high temperature tolerance

Product Description

Ceramic heat exchanger is widely used in iron and steel,machinery,building materials,petrochemical, non-ferrous metal smelting and other industries of all kinds of heating furnace, hot stove, heat treatment furnace, furnace, baking equipment, melting furnace and soaking pit, oil and gas boiler furnaces, the technology is through the reversing device makes two endothermic heat regenerator alternation, maximize the recovery of flue gas heat, and the combustion air and gas heated to 1000 ℃above, even if low calorific value of inferior fuel such as blast furnace gas) can realize stable and efficient combustion fire, can save fuel 40 ~ 70%.Production increased by more than 15%, fell by more than 40%, oxygenation loss of billet NOx emission is less than 100 PPM, flue gas emission temperature below 160 ℃, greatly reduce the greenhouse effect of the earth.

Parameter of product

Item | Unit | Data |

Temperature of application | ℃ | ≤1380℃ |

Density | g/m³ | ≥3.02 g |

Open porosity | % | <0.1 |

Bending strength | Mpa | 250(20℃) |

Mpa | 280(1200℃) | |

Modulus of elasticity | Gpa | 330(20℃) |

Gpa | 300(1200℃) | |

Thermal conductivity | W/m.k | 45(1200℃) |

Coefficient of thermal expansion | K-1x10-6 | 4.5 |

Rigidity | 13 |

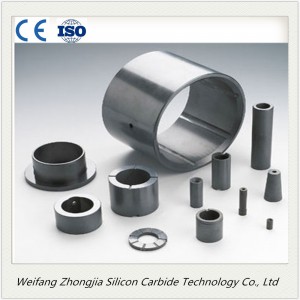

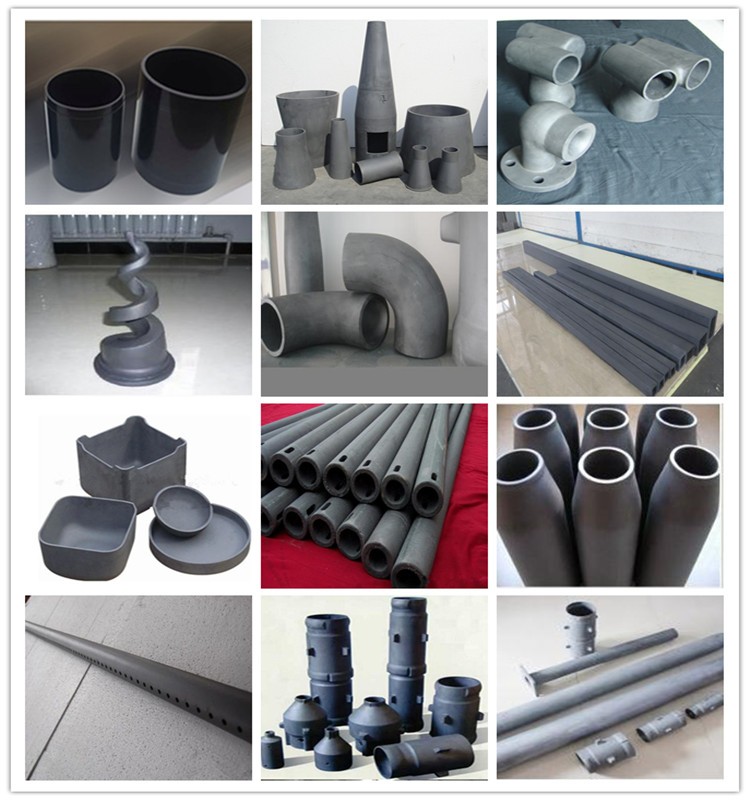

Product show:

The product is widely used in all kinds of heating furnace, oil and gas boiler furnace,

melting furnace,heat treatment furnace,baking equipment, hot stove and soaking pit of

petrochemical,iron & steel, machinery, building materials,non-ferrous metal and other

industries.The following are our product show.

Characteristics:

1:High temperature tolerance

2:Refractory

3:Excellent oxidating resistance.

4:High thermal conductivity

5.Long service life

Packaging & Shipping

Packing:standard export wooden case with foam inside

Shipping:According to you qyt.Normally 30 days after your deposit

Our Services

1. Your inquiry related to our products or prices will be replied within 24hours

2. Competitive prices based on same quality.

3. Fast delivery

4. After-service

Company Information

Weifang Zhongjia Silicon Carbide Technology Co.,Ltd is a professional,high technology company of manufacturing silicon carbide ceramics.

The main items are SiSiC Burner nozzles, Radiation pipe,Crucibles, Saggers, Beams, Rollers, Thermal couple protection tube, Desulphurization spray nozzles, Cooling air pipes, Sealing products etc.

The SiSiC items have good properties such as high temperature tolerance, high hardness, corrosion resistance, etc. They are widely used in the ceramic industry, glass-ceramic industry ,mineral processing industry,industry furnace,steel industry,petroleum industry,chemical industry,machinery industry,aerospace industry and other industries.

Our company owns an advanced vacuum sintering furnace and consummate porductchecking eqipment,which are passed through ISO9001 2000. The production process is imported from Germany.We can give you competitive prices and best service.

FAQ

1.Q: Are you trading company or manufacturer ?

A: Yes, Weifang Zhongjia is a manufacturer of sisic ceramic products.We can give you best price and quality for the same products. And we can reduce delivery time through effective communication.

2.Q: What is necessary for a quote?

A: Your drawing if possible, quantity, tolerance requirements, etc.

3.Q: How long is your delivery time?

A: Normally 30 days after deposit, it is according to quantity.

4.Q: What is your terms of payment ?

A: T/T

Any problem,please feel free to contact me.

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection