Performance featuresrnEdit

1. Light: 0.1-0.4 times the density of aluminum metal.

2. High ratio stiffness: its bend-resistant ratio is 1.5 times that of steel.

3. High damping damping performance and impact energy absorption: damping performance is 5-10 times that of aluminum metal.rnWhen a foam aluminum with a porosity rate of 84% is 50% variant, it absorbs more than 2.5MJ/m3 of energy.

4. Good acoustic function:

(1) Sound insulation performance (closed hole): between 800-4000HZ on the frequency of sound waves, the sound insulation coefficient of closed-hole foam aluminum is more than 0.9.

(2) sound absorption performance (microthrough hole and through hole): when the sound frequency is between 125---4000HZ, the sound absorption coefficient of through-hole foam aluminum can be up to 0.8, and its octave average sound absorption coefficient is more than 0.4.

5. Excellent electromagnetic shielding performance: when the electromagnetic wave frequency is between 2.6-18GHZ, the electromagnetic shielding of foam aluminum can reach 60-90dB.

6. Good thermal performance: the pore rate is 80---90% closed-hole foam, equivalent to marble.rnThrough-hole foam aluminum has good heat dissipation under forced convection conditions because its holes are connected to each other.

7. Do not burn and have good heat resistance.rnCorrosion resistance, good weather resistance, low moisture absorption, non-aging, non-toxic.

8. Easy to process: easy to cut, drill, bonding, molded can be bent into the desired shape, can be used organic or inorganic paint surface treatment, can be two sides of skin, forming a large size of light, high stiffness plate.

9. Easy to install: foam aluminum material can be installed at high altitudewith without mechanical lifting equipment, such as: ceiling roofs, walls and roofs, etc., can be mechanically connected or directly screwed and fixed, can also be pasted with adhesive on the wall or ceiling.

10. The sandwich structure formed by the sheet metal - foam aluminum - the sheet metal inherits the excellent performance of foam aluminum, and has a high bending strength, which can be used as a new building material, locomotive vehicle sorgand structure, etc.

Structural features

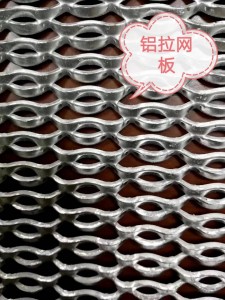

1. Larger aperture 0.3-7mm;

2. High and controlled porosity: 63%-90%;

3. 10---45cm2/cm3 is 10---45cm2/cm3 larger than the surface area;

4. Diversified hole structure; closed hole, through hole and micro-through hole foam aluminum;

5. Metal skeleton composition and hole structure can be controlled, can adapt to different needs.

Application areas:

Foam aluminum can be designed by changing its density and hole structure to design the desired comprehensive performance. That's what makes this unique material attractive.rnIt is therefore widely used in many fields:

1. Foam aluminum application range is very wide, the use of foam aluminum low density, high stiffness, sound insulation performance, thermal insulation performance, fire protection performance, absorption performance and heat-absorbing gas and other properties widely applicable to the rail transportation industry.rnSuch as the carrier and the assembly compartment insulation, energy absorption and fire, anti-virus components.

2. Using the sound insulation, sound absorption performance and energy absorption performance of foam aluminum, it is used in environmental protection areas in urban construction, such as soundproofing screens, and the automobile manufacturing industry is used in energy-absorbing elements and sound-absorbing elements, such as bumpers and silencers.

3, the use of foam aluminum low density, high stiffness, low thermal conductivity, widely used in energy-saving buildings, such as: insulation walls and fire barrier hot, energy-saving mobile room.

4. Can be used in the military industry, sound-absorbing and anti-magnetic components, such as: tanks, submarine shell splints.

5. Other machinery manufacturing, aviation industry and other products of thermal insulation, shock-absorbing, energy-absorbing components can be made of foam aluminum materials.

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection