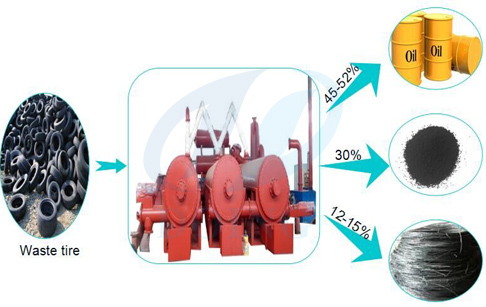

Continuous manufacture waste tire to oil pyrolysis plant

US $ / Set

Min. Order : 1 unit

Contact Supplier-

Type:Energy & Mineral Equipment

-

Brand Name:DY

-

Place of Origin:China (Mainland)

-

Port:Qingdao/Shanghai

-

Production Capacity:22 Set/Sets per Month

Product Details

Continuous manufacture waste tire to oil pyrolysis plant

Continuous manufacture waste tire to oil pyrolysis plant is a brand new refinery based on intermittent tire refining equipment. It uses PLC control system to reduce human error and labor costs. And the equipment truly 24 hours a day, continuous feed, continuous slagging, greatly improving production efficiency.

Continuous manufacture waste tire to oil pyrolysis plant working process

Our continuous manufacture waste tire to oil pyrolysis plant workflow includes the collection of waste tires, broken tires, continuous pyrolysis of these processes, the specific process is as follows:

1.Collect waste tires

In order to ensure the continuous operation of equipment, we must first collect enough waste tires.

2.Broken tires

Put the waste tires collected into the drawing machine and pull out the steel wire from the waste tires.

3. The wire pulled out of the tire into the tire crusher, the broken tire to spare.

4. Continuous pyrolysis

Tire debris into the continuity of tire cracking equipment, through the pyrolysis system and cooling system to obtain refined oil.

Continuous manufacture waste tire to oil pyrolysis plant

The advantages of continuous manufacture waste tire to oil pyrolysis plant

are as follows:

1. Accurately calculate the system to ensure full cracking, high oil yield.

Indirect heating, long life.

3. Continuous feeding, continuous slagging, saving time and effort.

4. Automatic, PLC control, save manpower.

5. Pyrolysis reactor with internal rotation device, without the need for regular pause to replace the sealing material.

6. Single handling capacity, small footprint.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com