Weitai Ringding Type Rice Transplanter 2z-8300 Type From The Direct Factory

US $ /

Min. Order : 1 unit

Contact Supplier-

Type:Agriculture Machinery & Equipment

-

Brand Name:

-

Place of Origin:China (Mainland)

-

Port:

-

Production Capacity:0 per

Product Details

- Model NO.: 2Z-8300

- Application Field: Agriculture

- Planting Machine Type: Planting Machine

- Mechanization: Semi-Automatic Planting Machine

- Certification: CE, ISO9001:2008

- Brand: Weitai

- No. Rows: 8

- Working Efficiency: 0.2ha /H

- Trademark: WEITAI

- HS Code: 8432303100

- Application: Rice

- Function: Transplanting

- Power Source: Diesel

- Sowing: Dibble Seeder

- Condition: New

- Engine: 178 Manual Start

- Row Distance: 30cm

- Machinie Dimensions: 2410*2732*1300mm

- Origin: Weifang Shandong, China

Basic Info

Product Description

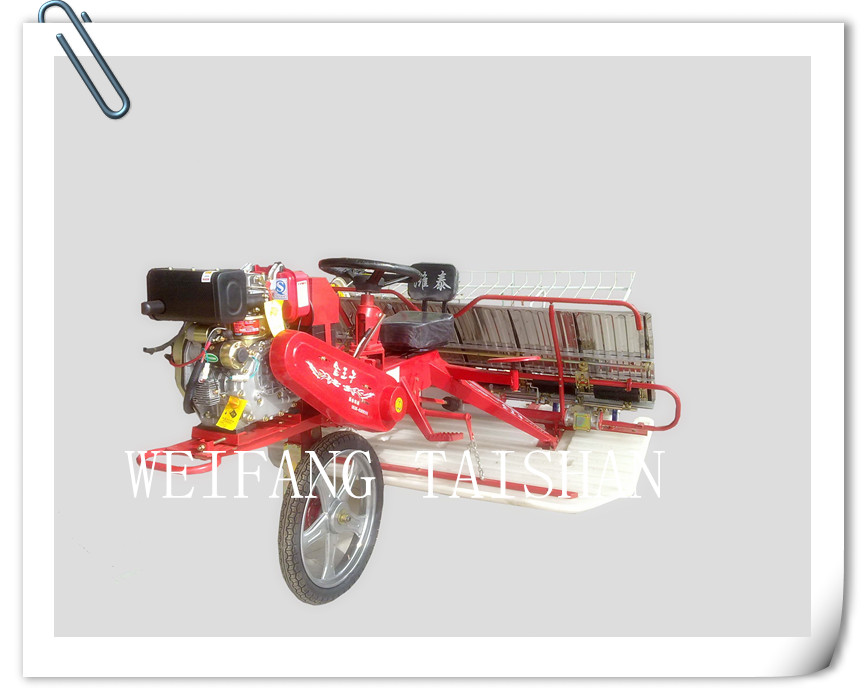

WEITAI RINGDING TYPE RICE TRANSPLANTER 2Z-8300 TYPE FROM THE DIRECT FACTORY

![Weitai Ringding Type Rice Transplanter 2z-8300 Type From The Direct Factory]()

1. Introduction

The riding type rice transplanter has been designed as simple structure, reasonable price ,satisfactory efficiency and easy repair. According to the row to row distance, there are two range of rice transplanter 300 mm and 238 mm type. According to row numbers, there are 6 row, 8 row,10 row type. Based on that, rice transplanter evolved into 6300, 8300, 8238 and 10238, four big range of rice transplanter.

In 2008, our factory has developed hydraulic over ride system which in used with rice transplanter, in order to ease the work strength of the rice transplanter driver. This system has been favorite by the farms. More importantly, this technology has been widely used in the transplanter product.

We have been keeping innovation of rice transplanter every year , in order to make our product having stable working performances, high efficiency, low consumption and best quality among riding type rice transplanter industry.

2. The main technical characteristics

a) Configured engine make the machine perform stable and low noise and more power. Electric start engine has higher working efficiency.

b) Adjustable steering system of this machine is divided into outside gear and inside gear. It can be adjusted forward and backward. Comfortable the user.

c) New adjustable humanity design seat makes the machine operate more comfortable and durable.

d) New-stainless steel seeding box make more anti-corruption.

e) Hydraulic over ride system can move the floating board upward, left up and right up.

f) Seeding distance can meet user's requirements under regulation.

g) Low noise designed transplanting arms can help driver judge transplanting condition timely .They even have much better performance than the old noisy transplanting arms.

h) Front adjustment for transplanting depth, user doesn't need to go to back to adjust the depth as before. This saves time and very convenient for user.

3. The product selling point

a) Good appearance and good quality

b) Good transplanting performance

c) Low failure rate

d) Provide global service support to client order on big quantity

e) CE Certificated product also avalible for optional

![Weitai Ringding Type Rice Transplanter 2z-8300 Type From The Direct Factory]()

1. Main specifications

5)Parts List

1. Introduction

The riding type rice transplanter has been designed as simple structure, reasonable price ,satisfactory efficiency and easy repair. According to the row to row distance, there are two range of rice transplanter 300 mm and 238 mm type. According to row numbers, there are 6 row, 8 row,10 row type. Based on that, rice transplanter evolved into 6300, 8300, 8238 and 10238, four big range of rice transplanter.

In 2008, our factory has developed hydraulic over ride system which in used with rice transplanter, in order to ease the work strength of the rice transplanter driver. This system has been favorite by the farms. More importantly, this technology has been widely used in the transplanter product.

We have been keeping innovation of rice transplanter every year , in order to make our product having stable working performances, high efficiency, low consumption and best quality among riding type rice transplanter industry.

2. The main technical characteristics

a) Configured engine make the machine perform stable and low noise and more power. Electric start engine has higher working efficiency.

b) Adjustable steering system of this machine is divided into outside gear and inside gear. It can be adjusted forward and backward. Comfortable the user.

c) New adjustable humanity design seat makes the machine operate more comfortable and durable.

d) New-stainless steel seeding box make more anti-corruption.

e) Hydraulic over ride system can move the floating board upward, left up and right up.

f) Seeding distance can meet user's requirements under regulation.

g) Low noise designed transplanting arms can help driver judge transplanting condition timely .They even have much better performance than the old noisy transplanting arms.

h) Front adjustment for transplanting depth, user doesn't need to go to back to adjust the depth as before. This saves time and very convenient for user.

3. The product selling point

a) Good appearance and good quality

b) Good transplanting performance

c) Low failure rate

d) Provide global service support to client order on big quantity

e) CE Certificated product also avalible for optional

1. Main specifications

| 1.Brand | WeiTai | ||

| 2.Model | 2ZT-8300BGE | ||

| 3.Dimention:L*W*H ( mm) | 2410*2732*1300 | ||

| 4.Net Weight(kg) | 420 | ||

| 5:Diesel Engine Model | 178F Electric tart | ||

| 6. Diesel Engine Output(kw/HP) | 4.05/5.5 | ||

| 7. Diesel Engine Rotating Speedr/min) | 1800 | ||

| 8.Number of Transplanting Row | 8 | ||

| 9.Row to Row Distance(mm) | 300 | ||

| 10.Hill to Hill Distance(mm) | 120,140 | ||

| 11.Transplanting Efficiency(Mu/H) | 3.5-5.5 | ||

| 12.Units Per 20ft Container | 6 | ||

| Units Per 40ft Container | 16 | ||

| 13.packaging size (L*W*H )(mm) | 2810*1760*600 | ||

| 14.G.W.(KG) | 480 | ||

5)Parts List

| Machine Assembly Parts | ||||||

| NO. | NAME | SPEC. | UNIT | MODEL | REMARK | |

| 2Z-6300B | 2Z-10238BG2 | |||||

| 2Z-8300BG2 | ||||||

| 2Z-6300BG2 | 2Z-8238B | |||||

| 2Z-8238BG2 | ||||||

| 2Z-6300BGE | 2Z-8238BGE | |||||

| QUANTITY | QUANTITY | |||||

| 1 | WORKING PART | SET | 1 | 1 | ||

| 2 | ENGINE | SET | 1 | 1 | ||

| 3 | TRACTION PART | SET | 1 | 1 | ||

| 4 | POWER FRAME | SET | 1 | 1 | ||

| 5 | WORKING TRANSMISSION BOX | SET | 1 | 1 | ||

| 6 | PADDY WHEEL | PC | 1 | 1 | ||

| 7 | WALKING WHEEL | PC | 1 | 1 | ||

| 8 | SEAT | PC | 1 | 1 | ||

| 9 | TRANSMISSION SHAFT | SET | 1 | 1 | ||

| 10 | SUPPORT FRAME | PC | 1 | 1 | ||

| 11 | TAIL WHEEL | SET | 2 | 2 | ||

| 12 | STRAP SHADE | PC | 1 | 1 | ||

| 13 | V- BELT | 1200 | PC | 2 | 2 | |

| 14 | 1245 | PC | 2 | 2 | BG SERIES | |

| 15 | 864 | PC | 1 | 1 | BG SERIES | |

| 16 | TRAVERSING MECHANISM | SET | 1 | 1 | ||

| 17 | STEERING WHEEL | PC | 1 | 1 | ||

| 18 | SUPPORT BOARD | SET | 2 | 2 | BG SERIES | |

| 19 | STRAP SHADE FRAME | PC | 1 | 1 | BG SERIES | |

| 20 | TOOLS BAG | PC | 1 | 1 | ||

| 21 | battery | SET | 1 | BG -E SERIES | ||

| ACCOMPAYING TOOLS AND SPARE PARTS | ||||||

| 1 | SOCKET WRENCH | S=30 | SET | 1 | 1 | |

| 2 | DOUBLE ENDED WRENCH | 16-18 | PC | 1 | 1 | |

| 3 | SLIP JOINT PLIERS | PC | 1 | 1 | ||

| 4 | CROSS POINT SCREW | PC | 1 | 1 | ||

| 5 | ENGINE OIL POT | PC | 1 | 1 | ||

| 6 | RETAINER PLIER FOR AXLE | 125-175 | PC | 1 | 1 | |

| 7 | RETAINER PLIERS FOR HOLE | 125-175 | PC | 1 | 1 | |

| 8 | FUNNEL | PC | 1 | 1 | ||

|

| ||||||